Pneumatic Soft Rolling Robot

-

Objective

Design your own soft robot that falls under one of the following categories covered in class: pneumatic soft actuators, origami robots, 3D printed meta materials, bistable or multistable actuators, or ring origami.

-

Outcome

Our group was inspired by pneumatic actuation but wanted to develop a different motion than the walking robots we learned about in class. Thus, we chose to build a rolling robot, which we felt may lead to more consistent motion.

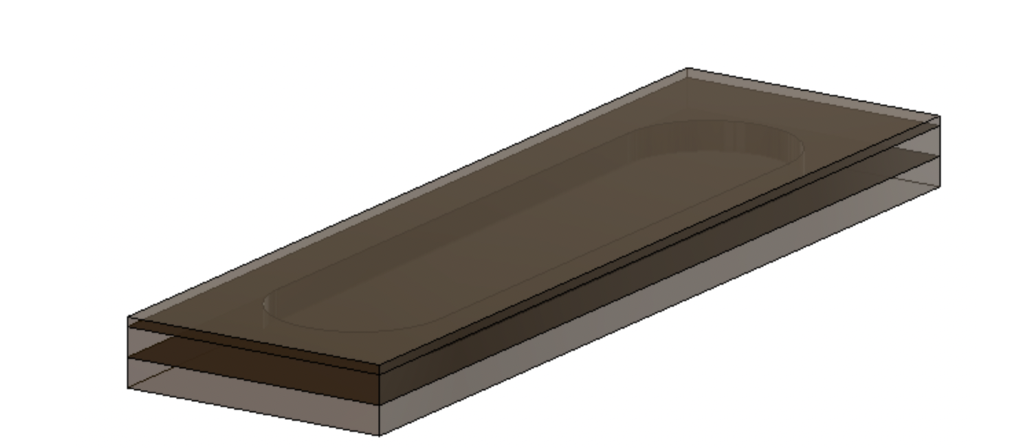

CAD

Abaqus Simulations

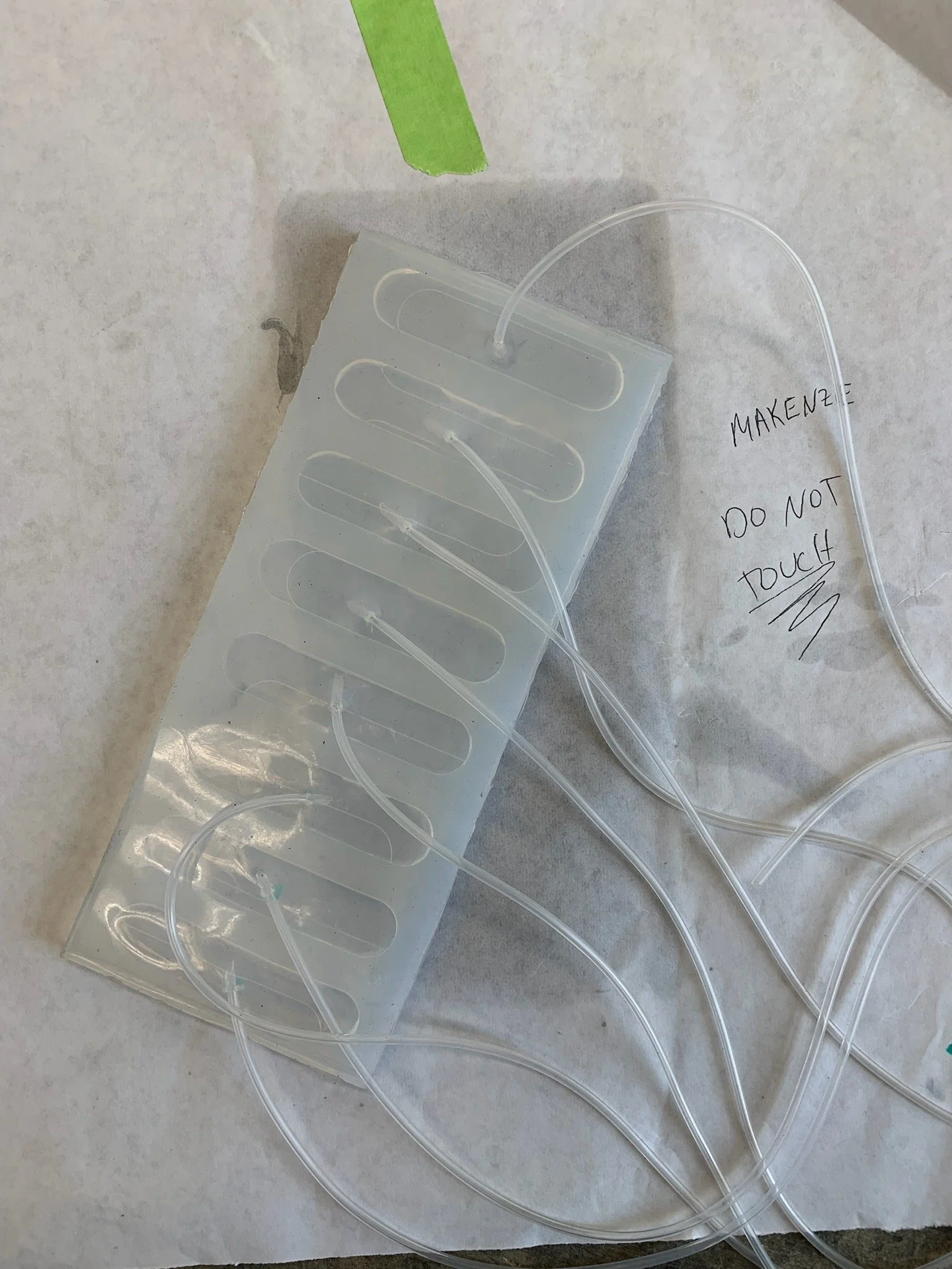

Modeled a single flat cavity because all eight cavities are identical and the data could be easily extrapolated to the others.

Three fixed sides to simulate the inner rigid cylinder and the thick silicone layer between the cavities.

Applied a pressure of 4.31 kPa to internal faces of the cavity, which is the max pressure that can be applied without material failure.

The results of the simulation showing the expected deflection of the cavity. The two bumps matched the deformation we saw in real life acuation.

The maximum displacement of the thin membrane is 15.8mm (0.62”) relative to the deflated membrane, which would be enough to impart a rotation of at least 43 degrees of the robot as shown in the figure on the right.

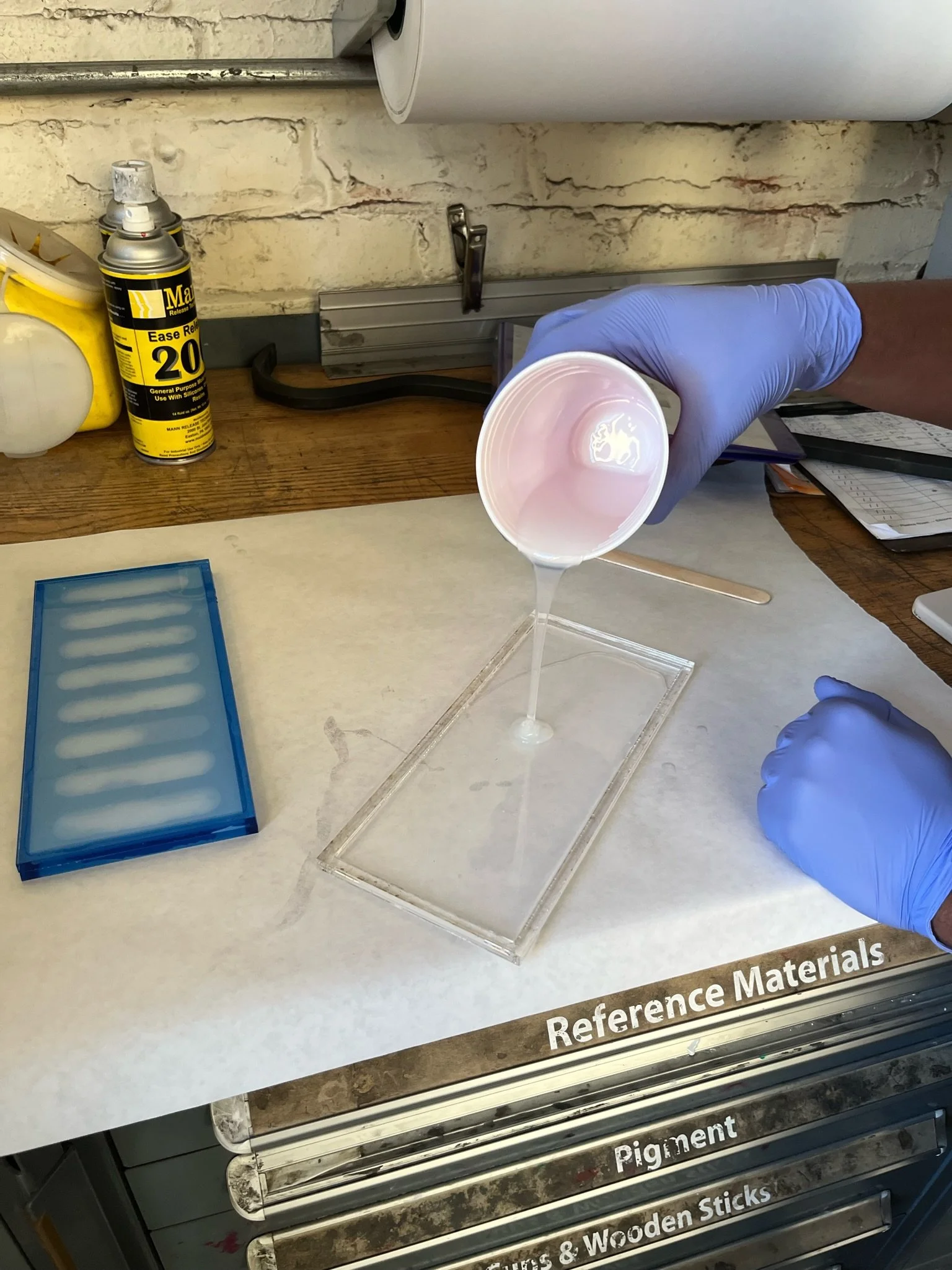

Fabrication

Results

initially we were nervous about rupturing the cavities, so we started conservatively with a 17mL injection volume. The robot consistently rolled forward about a 1/2 rotation before getting stuck between two cavities.

We then used a 60 mL injection volume, the max capacity of the syringe. With this the robot was able to roll a full revolution with each super inflated pouch acting as a hard stop to prevent backward rolling motion.

Ideas for Improvement

-

Decreasing the spacing between the inflation cavities would reduce the size of the stable region between the cavities, decreasing the probability of the robot settling between two cavities.

-

Additionally, increasing the number of cavities from 8 to 12+ would increase the resolution with which the orientation of the robot could be controlled, as well as decrease the angle that the robot could roll back on itself, which would serve to improve the accuracy with which the robot could be moved.

-

In order to make the robot work more smoothly, efforts could be made to improve the shape of the inflated cavity to reduce the tendency of the robot to roll backwards. One way of doing this would be to control the stiffness of the inflated membrane to create a shape that easily rolls in one direction but cannot roll in the other. This could be achieved with modifications to the membrane mold and additional analysis.

-

Lastly, integrating a position sensing and automatic inflation system would allow the robot to be much more precisely controlled and prevent actuation limitations from inhibiting the potential for the robot’s movement. An onboard air compressor and valving system would allow the robot to function without a tether, making this mechanism more attractive for use in real-world environments.