Fish Cork

-

Objective

Design a physical product that leverages the capabilities of additive manufacturing. Suggested topics include designing fixturing/tooling or incorporating algorithmic modeling.

-

Outcome

I chose to make a silicone wine bottle stopper as I was interested in learning about silicone molding. To incorporate the algorithmic modeling portion of the prompt, I chose to make a mass efficient 3D printed mold.

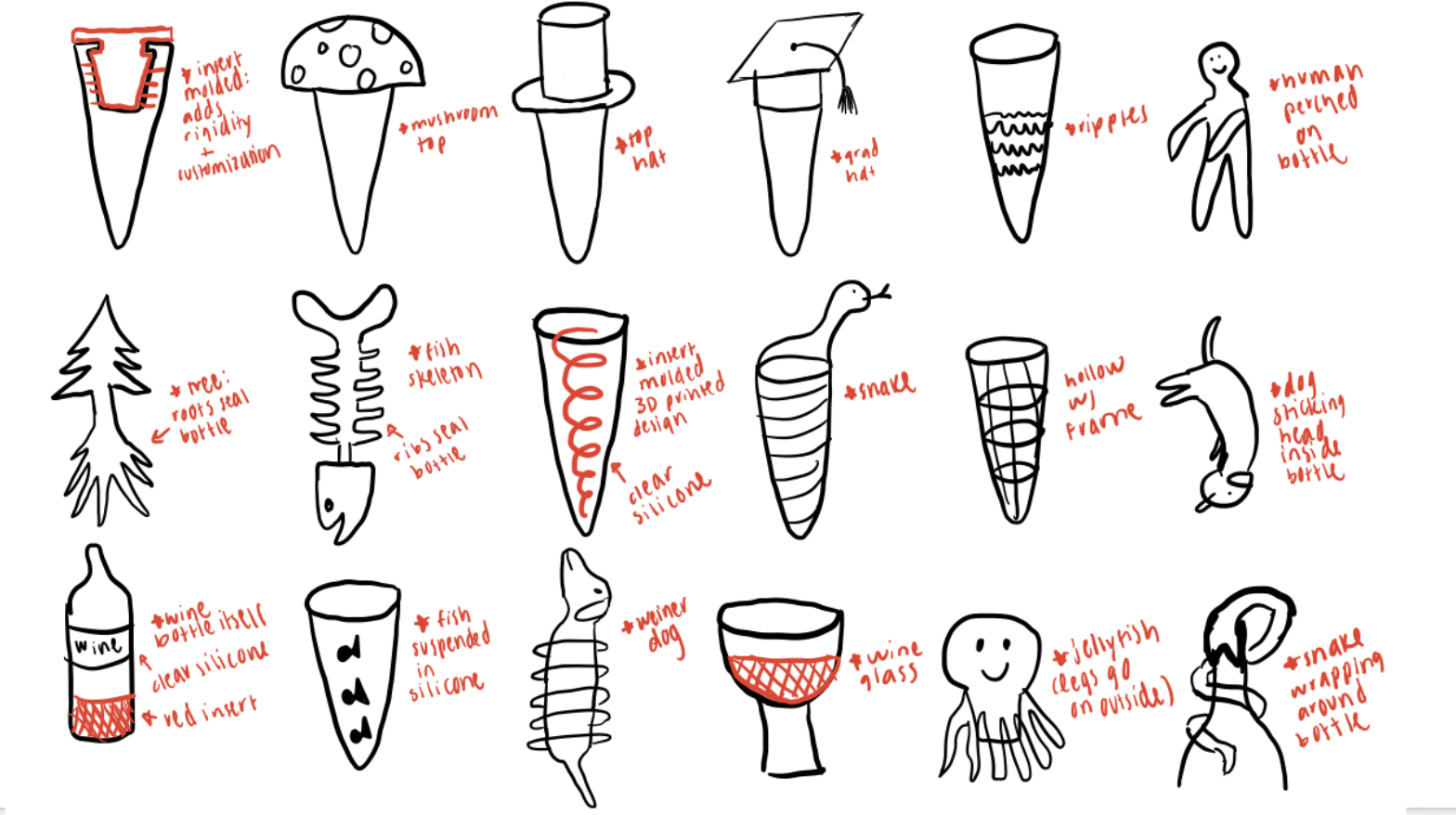

Original Ideation

Prototype 1

Goal: Get a feel for what the dimensions should be with a generic shaped stopper. Get a better understanding for what durometer silicone may be appropriate.

Leverage AM:

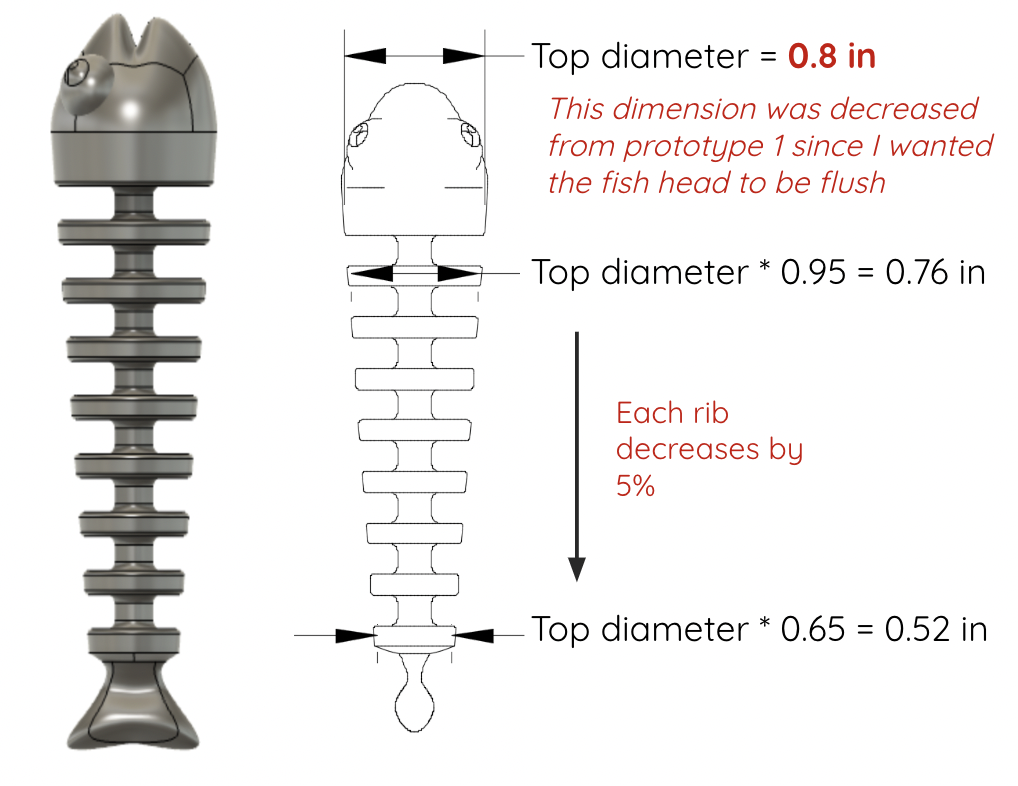

Prototype 1 had rather uninspiring geometry. I wanted to make sure I leveraged additive’s ability to capture complex geometry, so I ultimately landed on this skeleton fish design!

Prototype 2

Goal: Ensure the dimensions are right and that it can function as a wine stopper before making the mold.

Mold Design

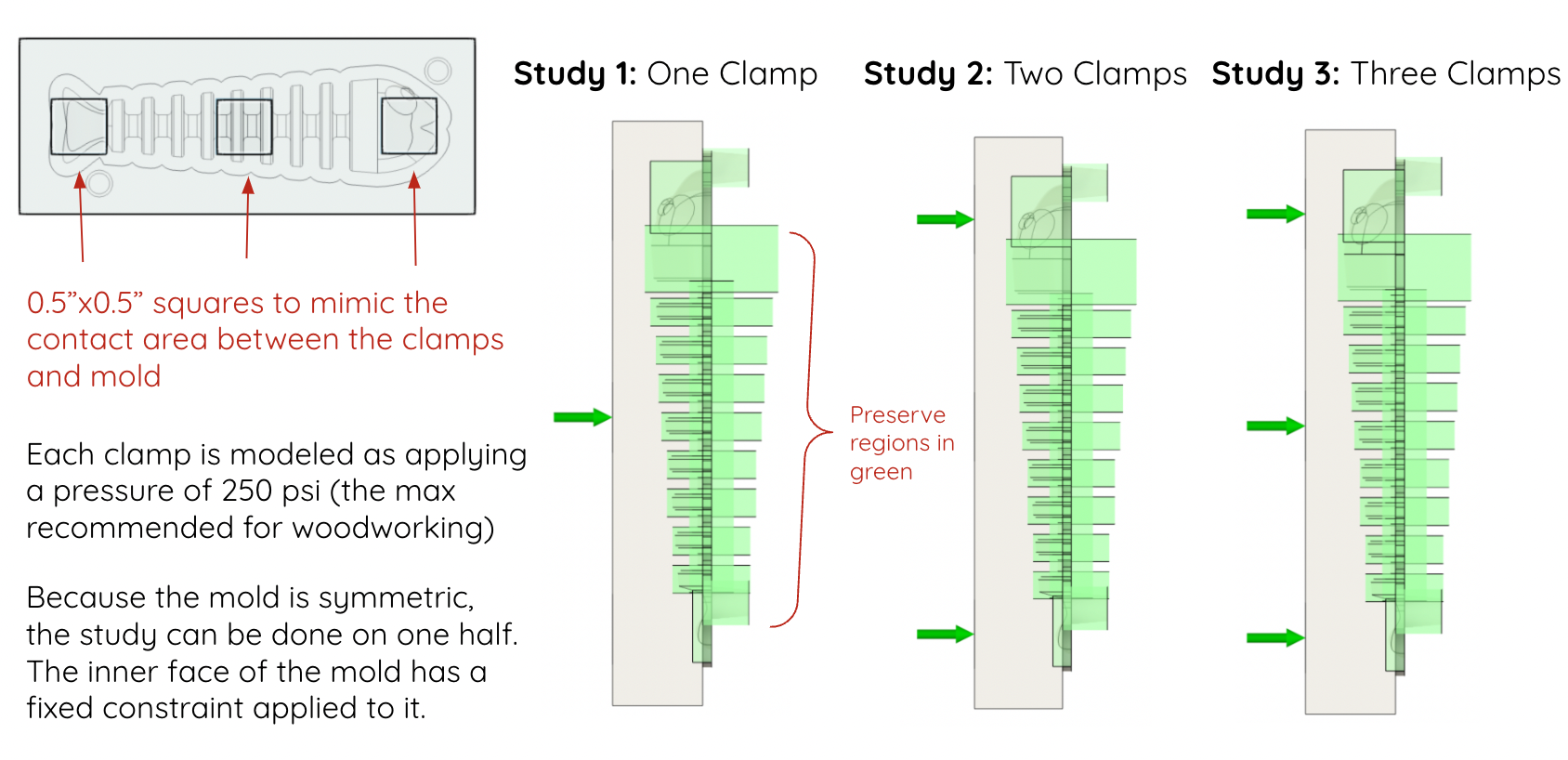

Started out with a generic square mold from which I could run shape optimization studies to see where material could be cut down! I wanted the mold to be mass optimal to decrease both cost and print time.

Shape Optimization Study

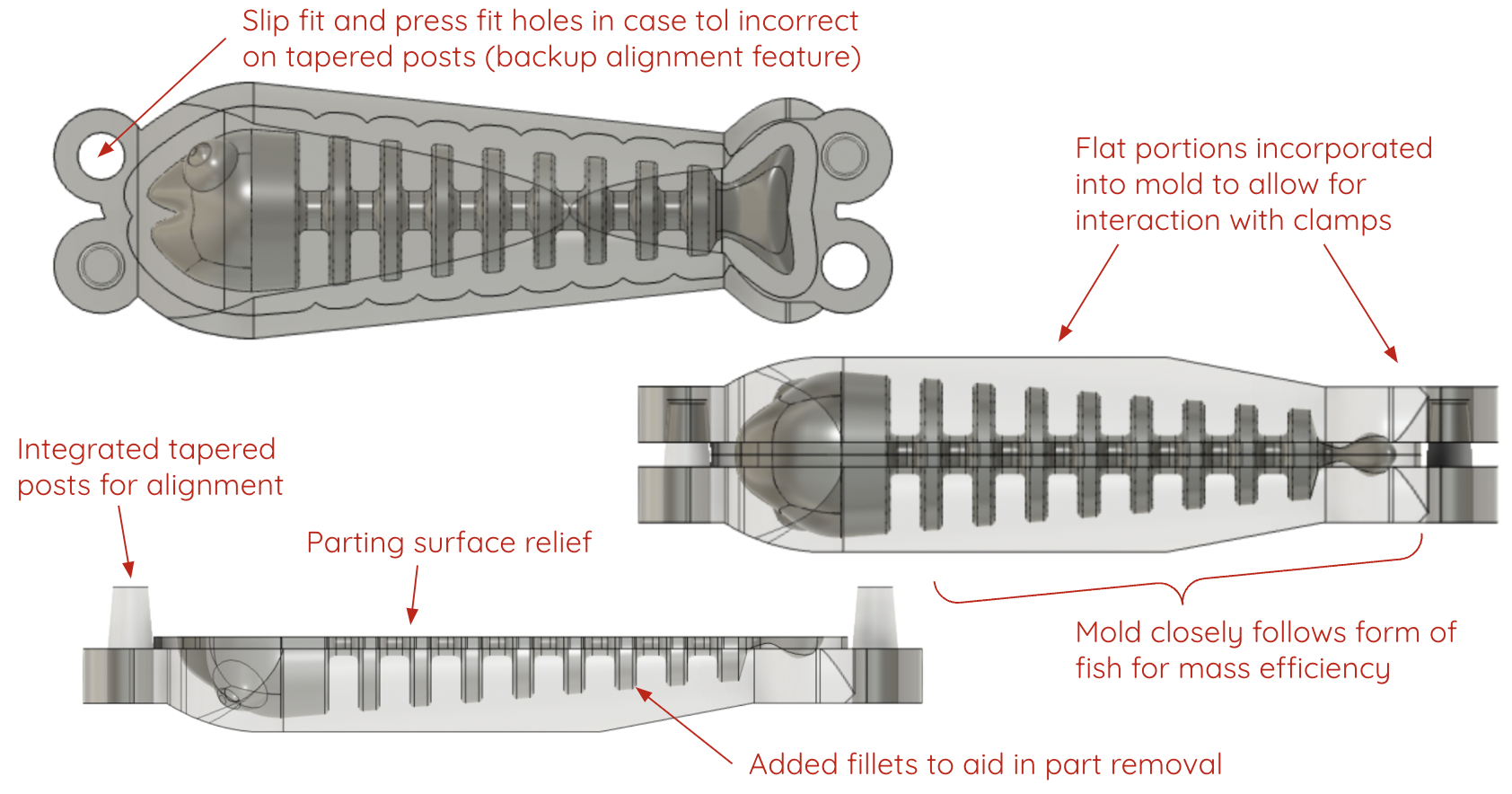

Updated Mold Design

Design Validation: Static Simulation

Goal: Confirm that the mass efficient mold can withstand the expected clamping force.